I have been working on how to handle the new version of the Yokohama balloons and revising some of my assumptions

The new form of the balloon is different from the original is that the inlet valve has been removed and the heat seal goes to the end of the tab. There is no paint on the inside of the plastic. Yokohama states on its web site that the film is nylon polyethylene. Thisshows the old valved balloon with the paint removed and the neck sealed for flight

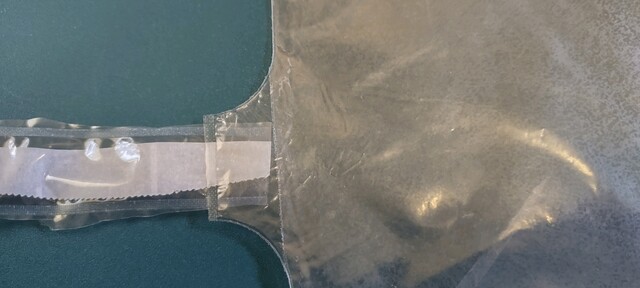

Photo 1828 shows the modified version of the valve. No paint and sealed to the end. Otherwise, it is the same lip and is rather short.

To deal with the short neck, make a polyethylene tube from a kitchen sandwich bag or some other poly bag. Cut a piece of kitchen parchment and place it in the poly tube (before sealing so it is easy to get it inside). Make sure it is longer than the tube or you will have trouble getting it out.

The impulse sealer then seals the end of the neck and the parchment prevents closing of the tube

The tube can be used for filling. Since it is small, a sandwich bag is strong enough to do the job.

The new filling tube can be heat sealed for pressure testing and the circumference can be used to check for leaks since a 2 inch loss of circumference is possi ble before the balloon is near zero superpressure, a reduction in circumference would indicate a leak. If it is in the new neck, it should be easy to check.

I have stretched this balloon to 103 inches and the pressure reached .45 psi.. I believe 105 might be a practical number to shoot for but I chickened out before a burst. At that time there is no trace of wrinkles along the seam. Remember humidity is important so the pressure you might need will be different if your humidity is higher. I’m in the Central Valley and it is dry right now. Deflating the balloon and refilling it was done to test the loss of volume from no internal pressure. Initially a 2.5 inch reduction in circumference was seen. The balloon was reinflated to 102 inches and to reach that, the pressure was .3 psi. This suggests that a higher superpressure might be used than I had expected and thus keeping the balloon at a larger volume. Stretching to 100 inches probably means flying at 98 inches circumference.

The fellow that flew balloons in the Antarctic suggested a higher superpressure than I had expected. He suggested .4 to .6 psi and the upper limit scares me a bit but certainly bears looking into. I will be looking for .3 psi max this time to just creep into his range a little at a time.

If this holds pressure like I expect, this will be what carried Kazus beacon up next week.

David

WB6TOU